A-STANDARD DOMESTIC WASTEWATER TREATMENT SYSTEM BY MBR TECHNOLOGY

1. What are the differences between MBR (membrane bio reactor) with other wastewater treatment technologies?

The characteristics of domestic wastewater are various impurities, of which 52% are organic, 48% are inorganic substances and a large number of microorganisms in the form of viruses and pathogenic bacteria. Domestic wastewater often contains quite high nutrient content (Nitrogen, phosphorus), so the most common treatment solution is still microbiological treatment.

MBR technology used to treat pollutants in wastewater is still based on biochemical reactions of normally suspended activated sludge but with additional bio-filtration equipment MBR to:

- Remove sediment tanks and disinfection tanks, because MBR membranes with micro-sized pores can filter most suspended solids (TSS) and bacteria (coliforms) in wastewater

- Build a wastewater treatment system in a small space

- Upgrade wastewater treatment capacity without the need of building more tanks

- Retain sludge in membrane tanks, sludge only disappears when sucked, does not worry about loss of passive sludge like biological sedimentation method.

- After-treatment water achieves high transparency

2. Are there many types of MBR? Which type is good?

MBR have many different types and brands, in order to select a good membrane, the following criteria should be paid special attention to:

- Transmembrane pressure (TMP): the higher the pressure, the worse the membrane material

- Membrane cleaning frequency: The more frequently the membrane requires to be cleaned (for example, once a week) or using a high concentration of chemicals to clean, proves that the material of MBR is not good and easily to get clogged.

- Membrane cleaning method: If the membrane must be taken out of from the tank to wash, this is an old, obsolete membrane technology. Advanced MBR technology must allow cleaning while membrane is still submerged in wastewater in reaction tank, there is no requirement to lift up membrane out of tank or empty the tank to conduct membrane cleaning.

3. How is the MBR system design provided by NGO?

System design is extremely compact, consists of only 1-2 main reaction tanks, can be designed underground, on the ground or semi-underground.

The total required space of the treatment system is always smaller than the total discharge capacity per day, especially saves space and construction investment cost.

- Illustration of Treatment system

- Processing description

Pretreatment: Pretreatment process is very important because it eliminates coarse solids in order not to clog the pumps and water transmission pipe system. Then, grease removal compartment with the purpose of not hindering useful microbiological process in treatment station. Fats and oil separation compartment is especially necessary for the treatment of wastewater from cafeterias.

Balancing tank: Due to the operational characteristics of the plant, much water used during the day, and less at night, the wastewater flow is constantly changing and has a large difference. Therefore, it is necessary to have a balancing tank in order to prevent shock load for bio-treatment system.

Anoxic treatment tank: Eliminating NO3, anoxic micro-organisms using nitrate (NO-3) instead of oxygen. Therefore, it is necessary to reflux water containing nitrate. To enhance the treatment efficiency, the tank is designed to be attached by a submerged mixer. This tank can be removed if the customer does not have enough space and footprint for the system.

Aerobic & MBR: This is the central treatment compartment of system before the effluent is drained out. Very high density micro-organisms and sticking to a surface membrane will completely remove pollutants such as Ammonia NH4, part of BOD, Nitrate. Meanwhile, this membrane shall filter the untreated components due to overloading to circulate through the reflux pump for thoroughly treating the wastewater.

One feature of domestic wastewater is ~ 48% inorganic, non-biodegradable, and not all organic substances will be decomposed by microorganisms, therefore, the membrane shall play a very important role in removing most of these substances together with sludge, including coliforms, to ensure that the outlet water meets A standard or above in a stable manner, without the addition of sterilization chemicals to treat coliforms.

Sludge storage tank: To store excess sludge generated during the treatment process, partially drying the sludge prior to the transportation for treatment in the form of solid or liquid disposal.

4. Does NGO use any different MBR technology?

Yes, NGO use MBR-X membranes with 3D material structure, the water distribution structure follows 6 ports (instead of 1 port as most common membranes available in the market); Transmembrane pressure is particularly low, can be the lowest among membrane technologies in the market; The frequency of membrane cleaning is very low (~ once a month) with only 0.5% NaCLO solution, which can be easily and washed inside the treatment tank and much more convenient for operators. This is the technology that has 7 patents and has been applied in more than 300 projects all over the world.

5. Is the maintenance of the wastewater treatment system expensive?

Enterprises only spend less than VND 2,000/ m3 to maintain the wastewater treatment system with MBR technology

6. What is the quality of after-treatment water committed by NGO's?

NGO has the ability to commit to after-treatment water meeting quality standard by inheriting technology from strategic cooperation with manufacturers and the experience accumulated through hundreds of MBR projects implemented. We will support enterprises to monitor their water quality daily publicly and independently to ensure water quality as committed.

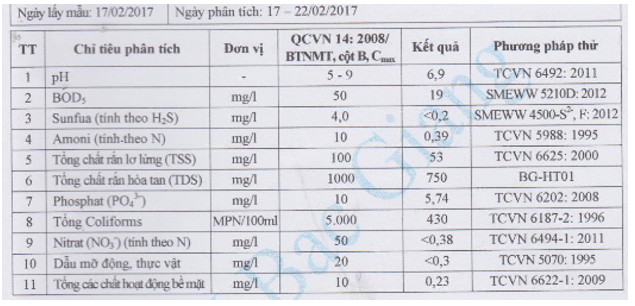

Pollution concentration of domestic wastewater and water quality achieved and stabilized after treatment at one project of NGO.

If your business is interested in solution to inlet water treatment, or has a demand for ion exchange materials, please contact NGO via phone number (024) 3566 8225 or email office@8ngo.com for direct consultation.

thong_tin_lien_quan

-

Wastewater treatment

Wastewater treatment

-

A standard domestic wastewater

A standard domestic wastewater

-

B standard domestic wastewater

B standard domestic wastewater

-

Pig Farm Wastewater

Pig Farm Wastewater

-

Textile dyeing wastewater

Textile dyeing wastewater

-

Paper industry wastewater solution

Paper industry wastewater solution

-

Textile Dyeing Wastewater & Industrial Washing

Textile Dyeing Wastewater & Industrial Washing

-

Slaughter wastewater treatment solution

Slaughter wastewater treatment solution

-

Aquaculture wastewater

Aquaculture wastewater

-

Starch wastewater

Starch wastewater

-

Petroleum wastewater

Petroleum wastewater

-

Beer wastewater

Beer wastewater

-

Other industrial wastewaters

Other industrial wastewaters

-

BioPM - Organic Industrial wastewater treatment solution

BioPM - Organic Industrial wastewater treatment solution

-

MBR solutions

MBR solutions

-

Conventional activated sludge (CAS)

Conventional activated sludge (CAS)

-

Moving bed biofilm reactor (MBBR)

Moving bed biofilm reactor (MBBR)

-

Anaerobic- Anoxic-Aerobic (AAO)

Anaerobic- Anoxic-Aerobic (AAO)

-

Sequencing batch reactor (SBR)

Sequencing batch reactor (SBR)

-

Physical & Chemical methods

Physical & Chemical methods

-

Supply water treatment

Supply water treatment

-

Cooling system water

Cooling system water

-

Water treatment for food and Beverage production

Water treatment for food and Beverage production

-

Ultra pure water supply solution for electronic industry

Ultra pure water supply solution for electronic industry

-

Pure water supply for pharmaceutical manufacturers

Pure water supply for pharmaceutical manufacturers

-

Water Supply treatment with ion exchange method

Water Supply treatment with ion exchange method

-

Ordor Treatment

Ordor Treatment